1968 Fender Super Reverb

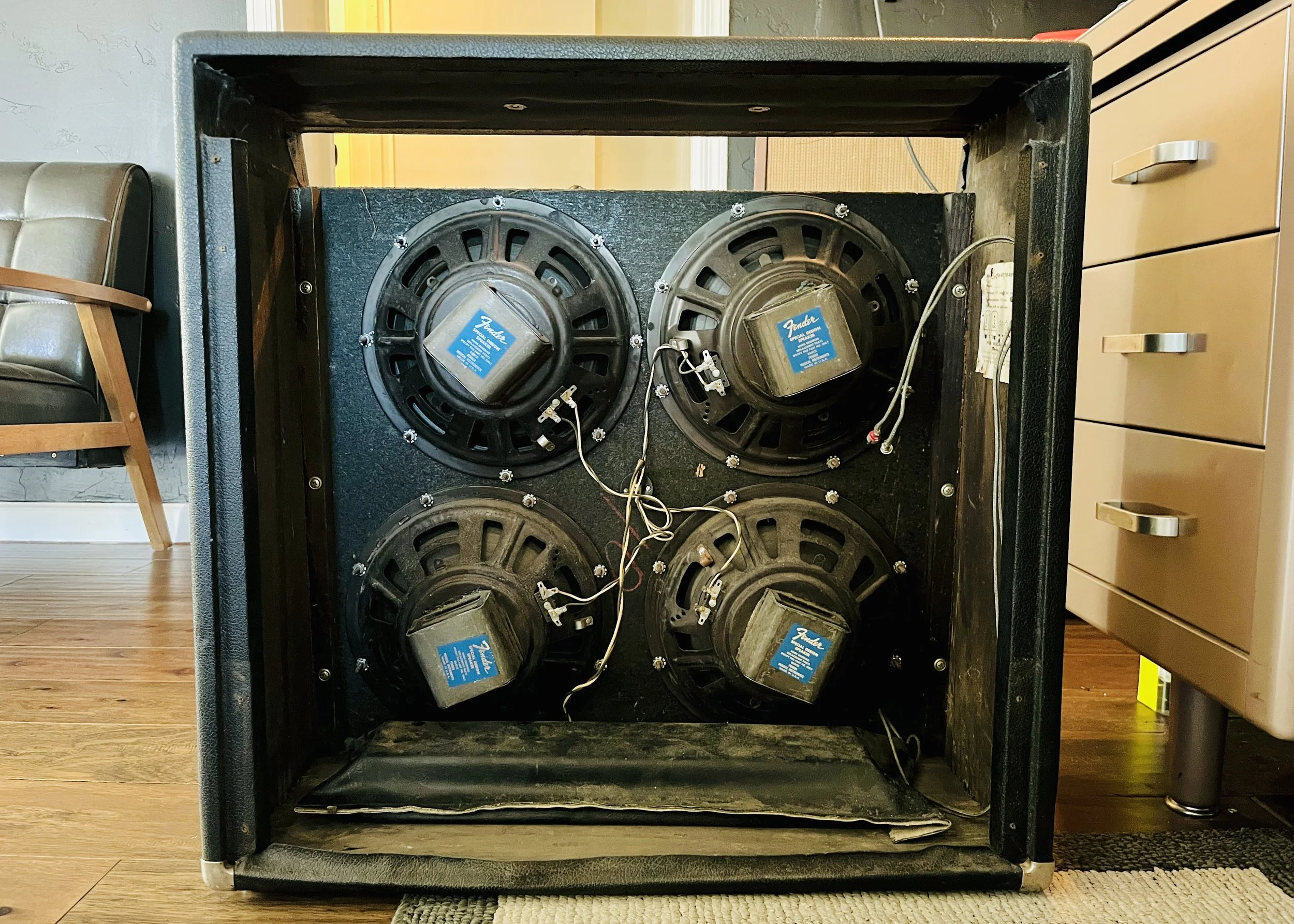

The Silver-Panel Fender Super Reverb is a favorite touring amp for some of the biggest known players in history. With 40 watts of power and 4x10” speakers this model sits a little more than halfway on the scale of most power in the classic Fender lineup. It’s a big and heavy amp with lots great bass response and output volume - being a bit less loud than a Twin Reverb. The Super Reverb has a larger 50 watt output transformer (same as the black-panel Bassman) than the other Fender 2 x 6L6 amps' standard 40 watt transformers. The larger transformer adds output volume and headroom and gives the Super Reverb a distinct voice. The Normal channel has only Treble/Bass controls while the Vibrato channel has an added Middle tone control. The Super Reverb's 2 ohm output transformer supplies the negative feedback circuit with 41% less voltage so it has less negative feedback than the 4 and 8 ohm 6L6 AB763 amps. Less negative feedback leads to a thicker clean tone, earlier dirt and a lazier transition to overdrive. The Super Reverb, and Concert use .022uF mid caps where all other AB763's use .047uF mid caps, this shifts the Mid tone control frequency band higher and reduces the mid scoop. Notable users include: Stevie Ray Vaughan, Derek Trucks, Robben Ford, East Bay Ray, and Fred “Sonic” Smith.

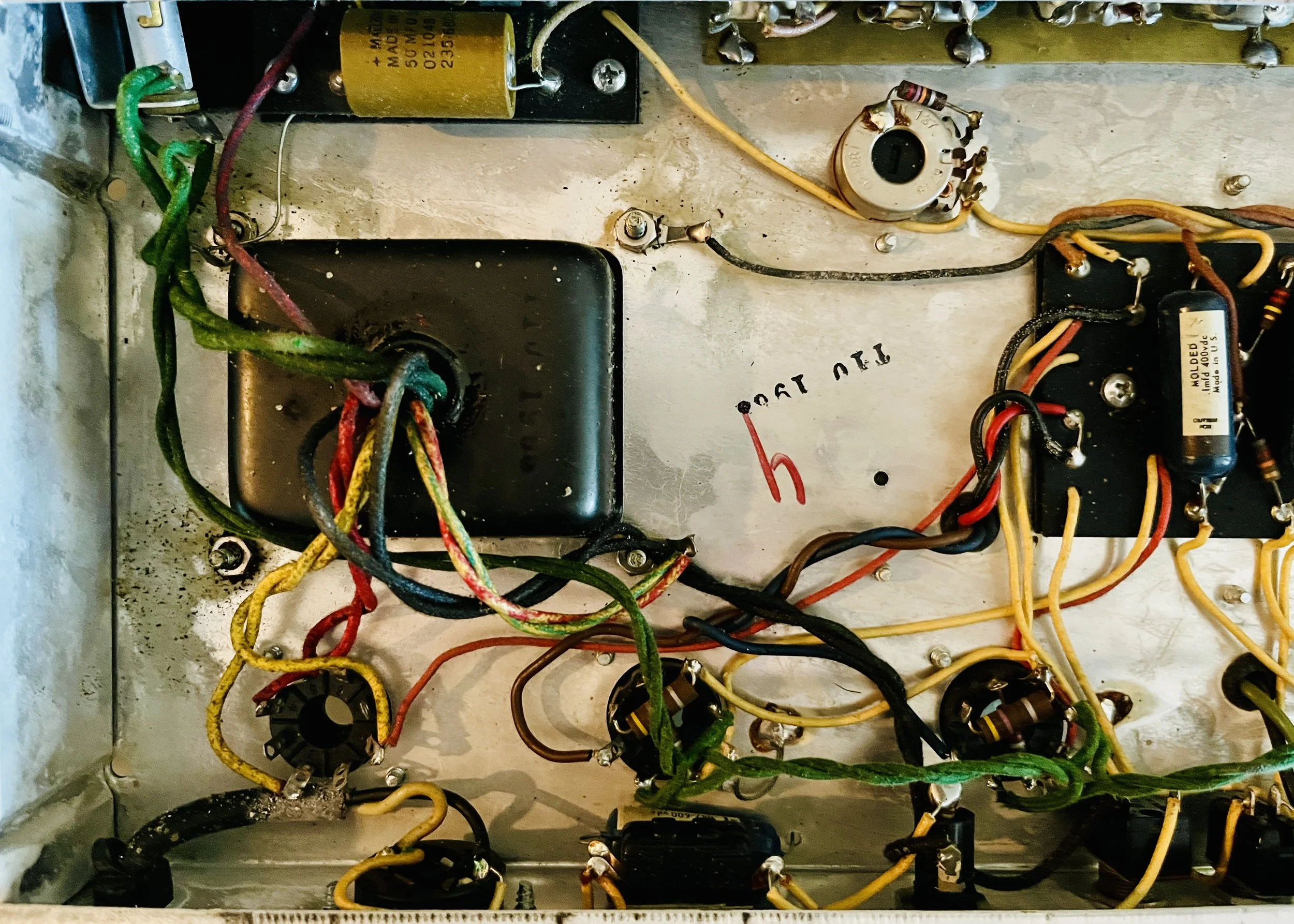

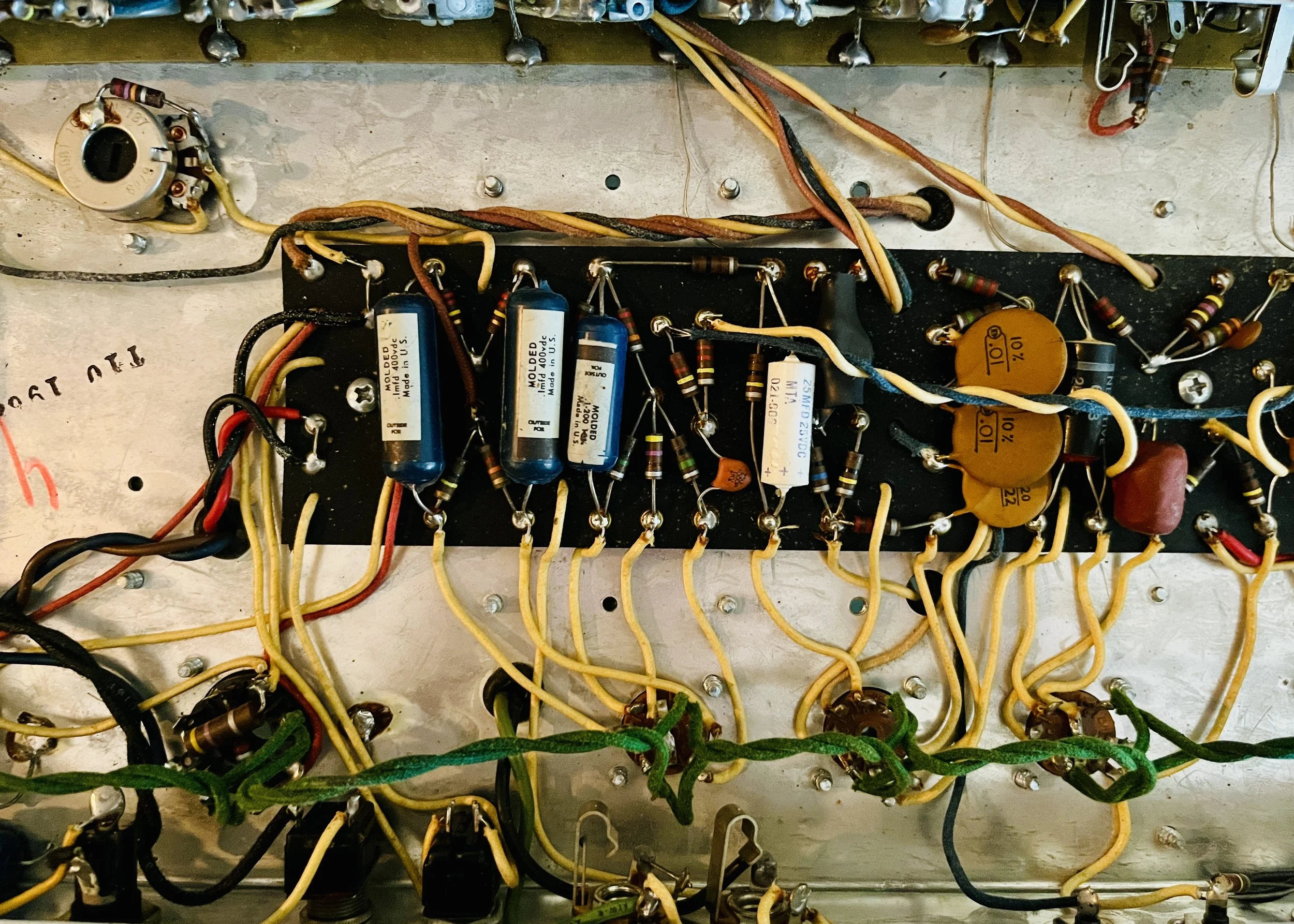

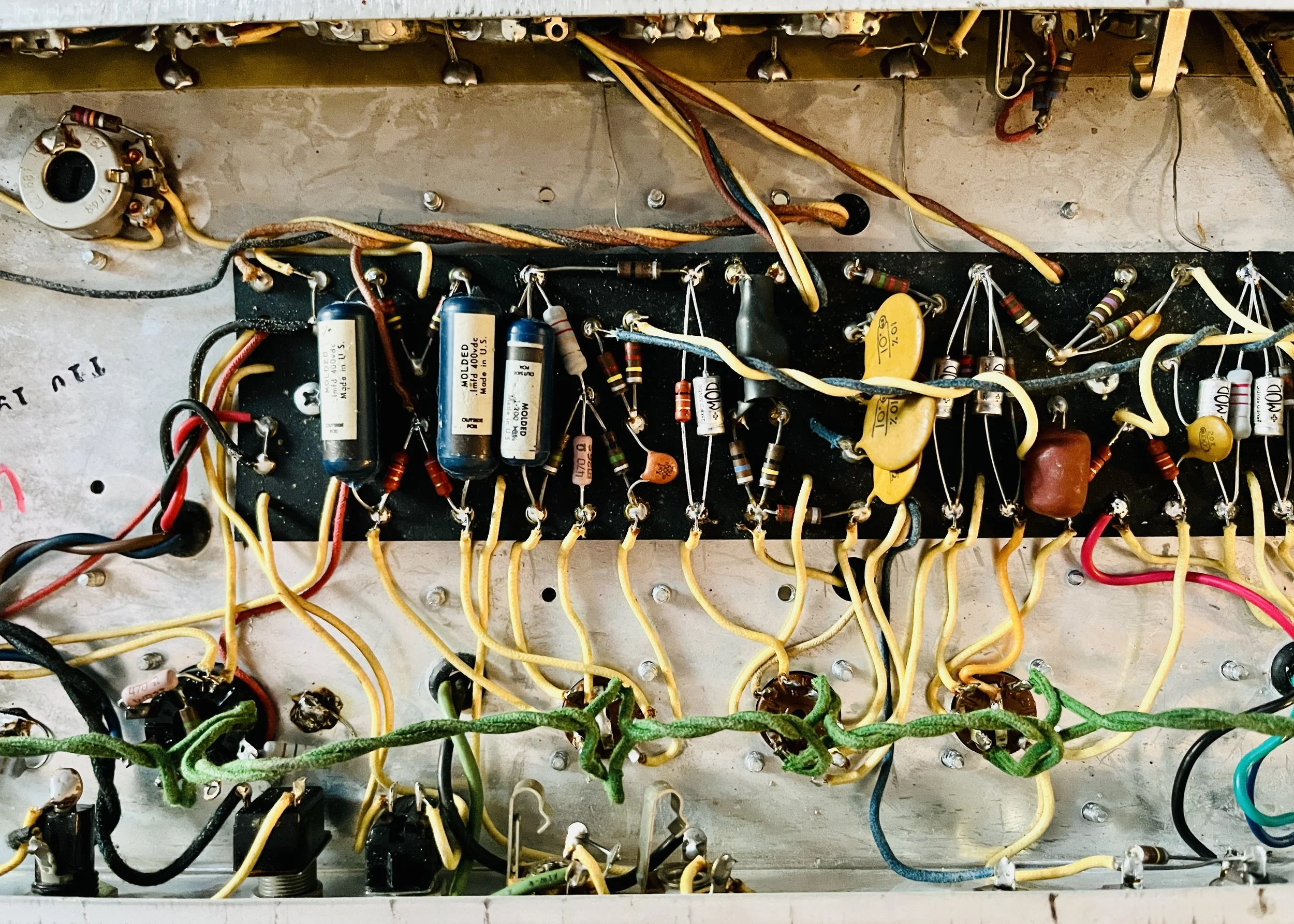

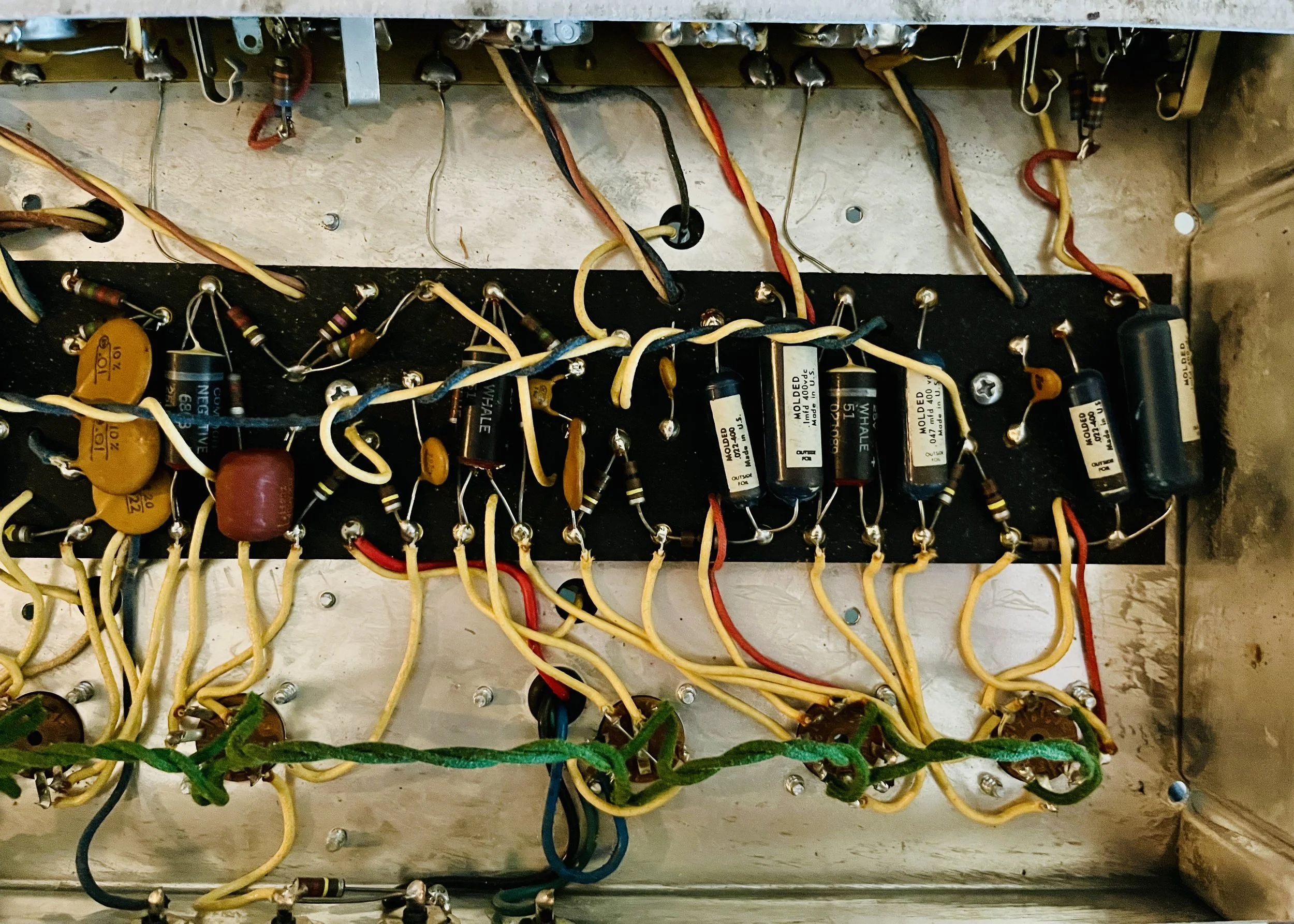

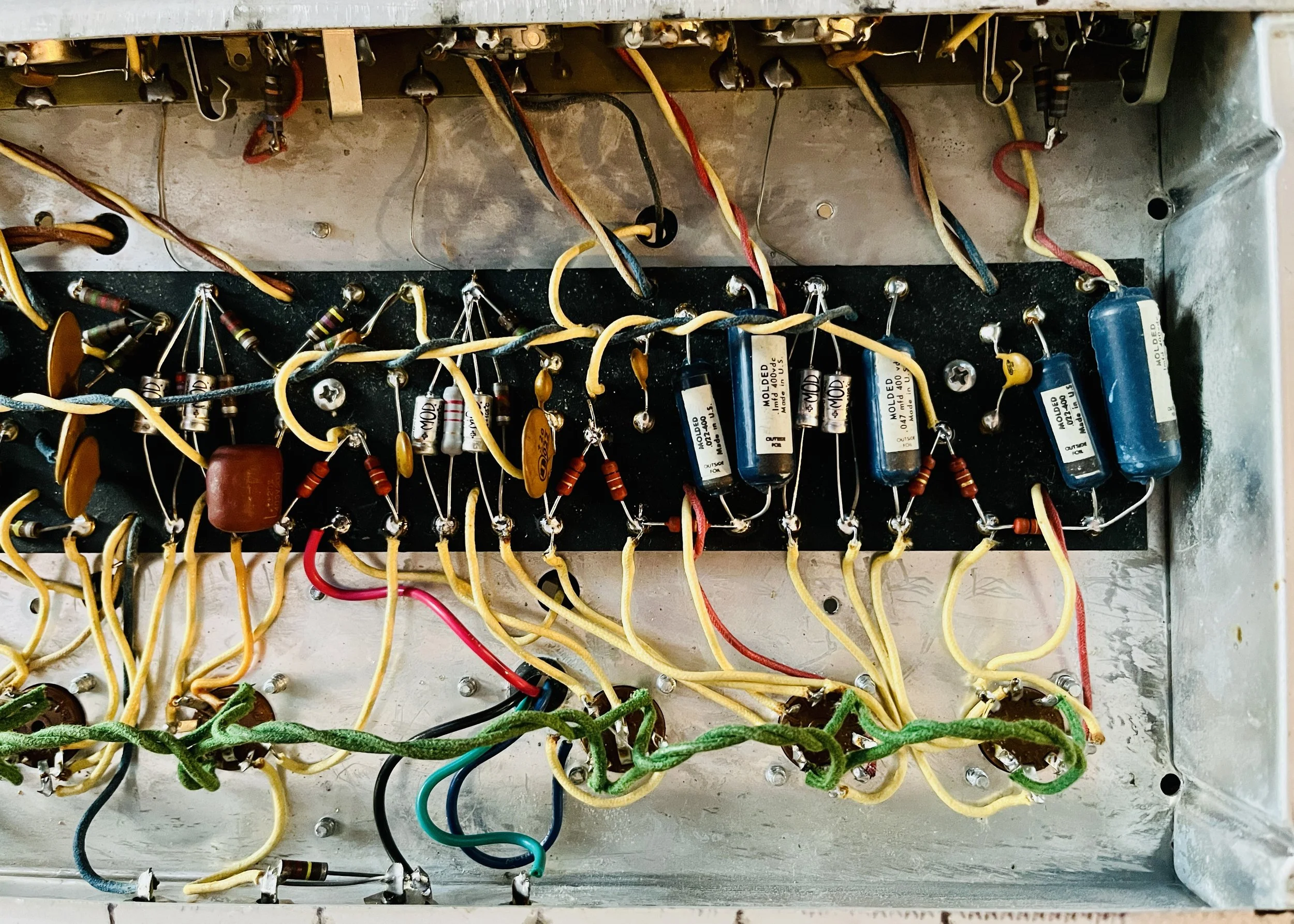

This amp came in to my shop in completely original condition. The electronics were untouched. This amp had leaking filter caps, some heat damaged resistors, a blown Reverb Driver Transformer, and some bad preamp tubes. It needed a full restoration including a cap job, new power dropping/plate/screen resistors, new Reverb Transformer, new tubes, 3 prong AC cord conversion, replacement hardware, and a good cleaning.

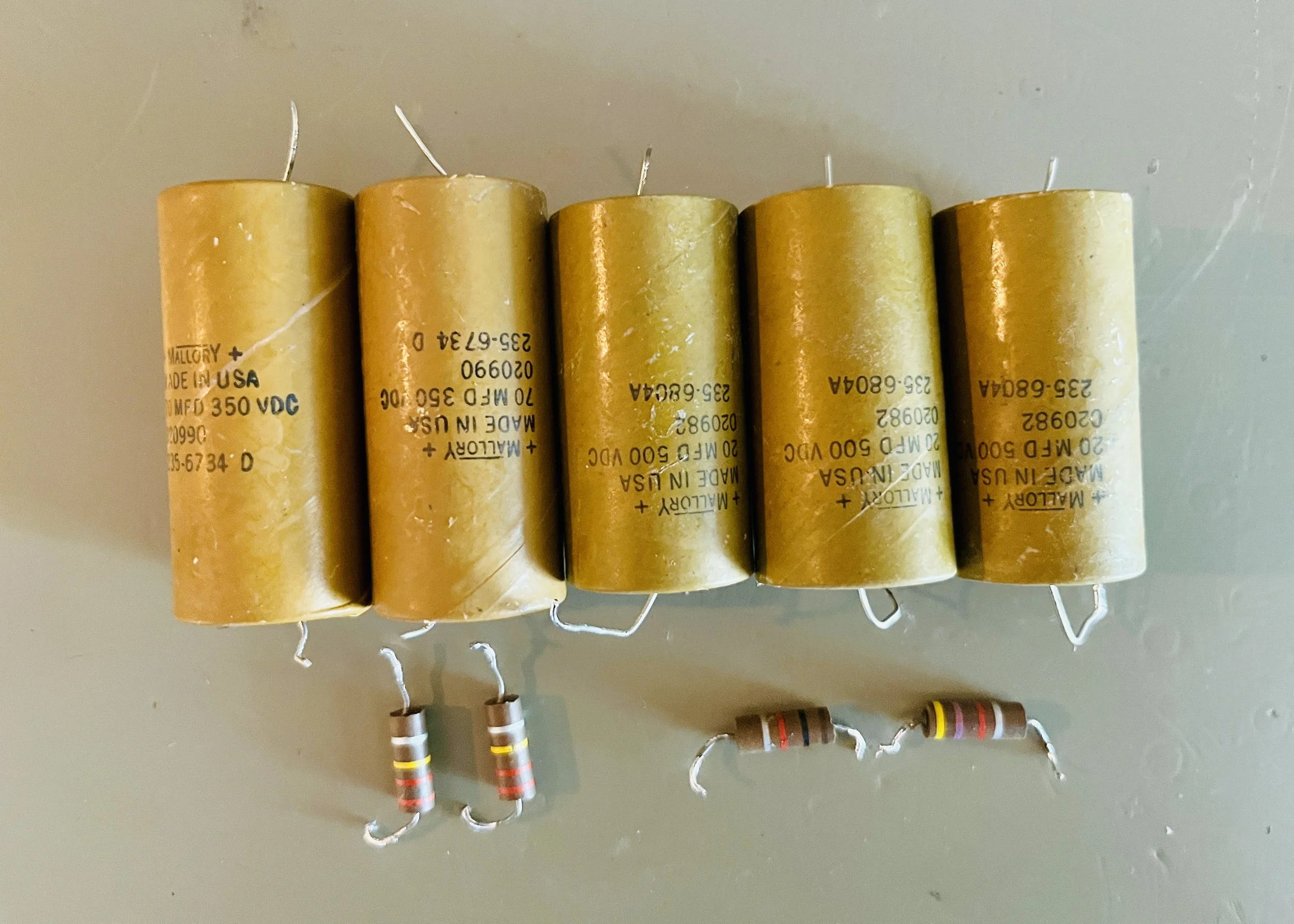

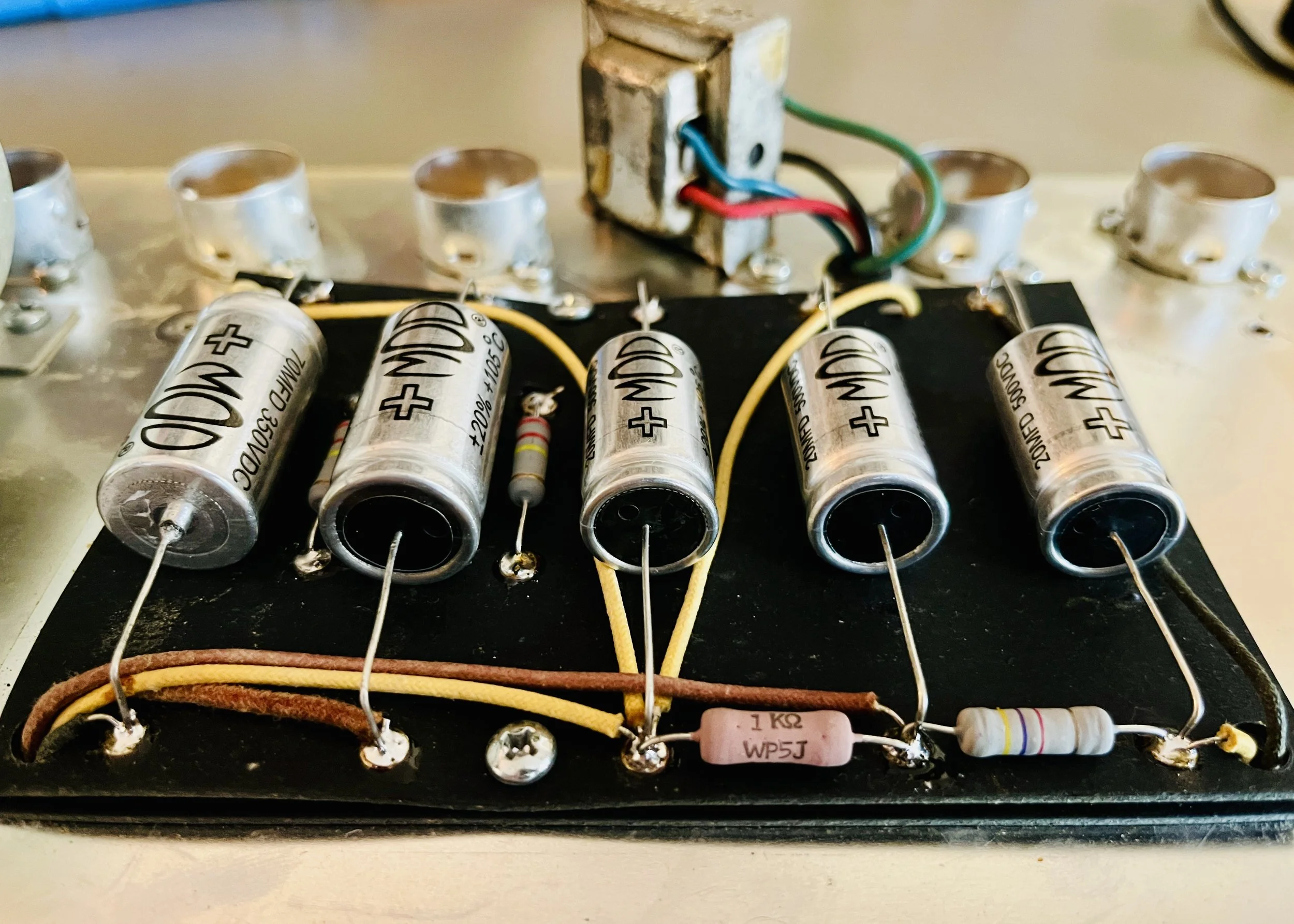

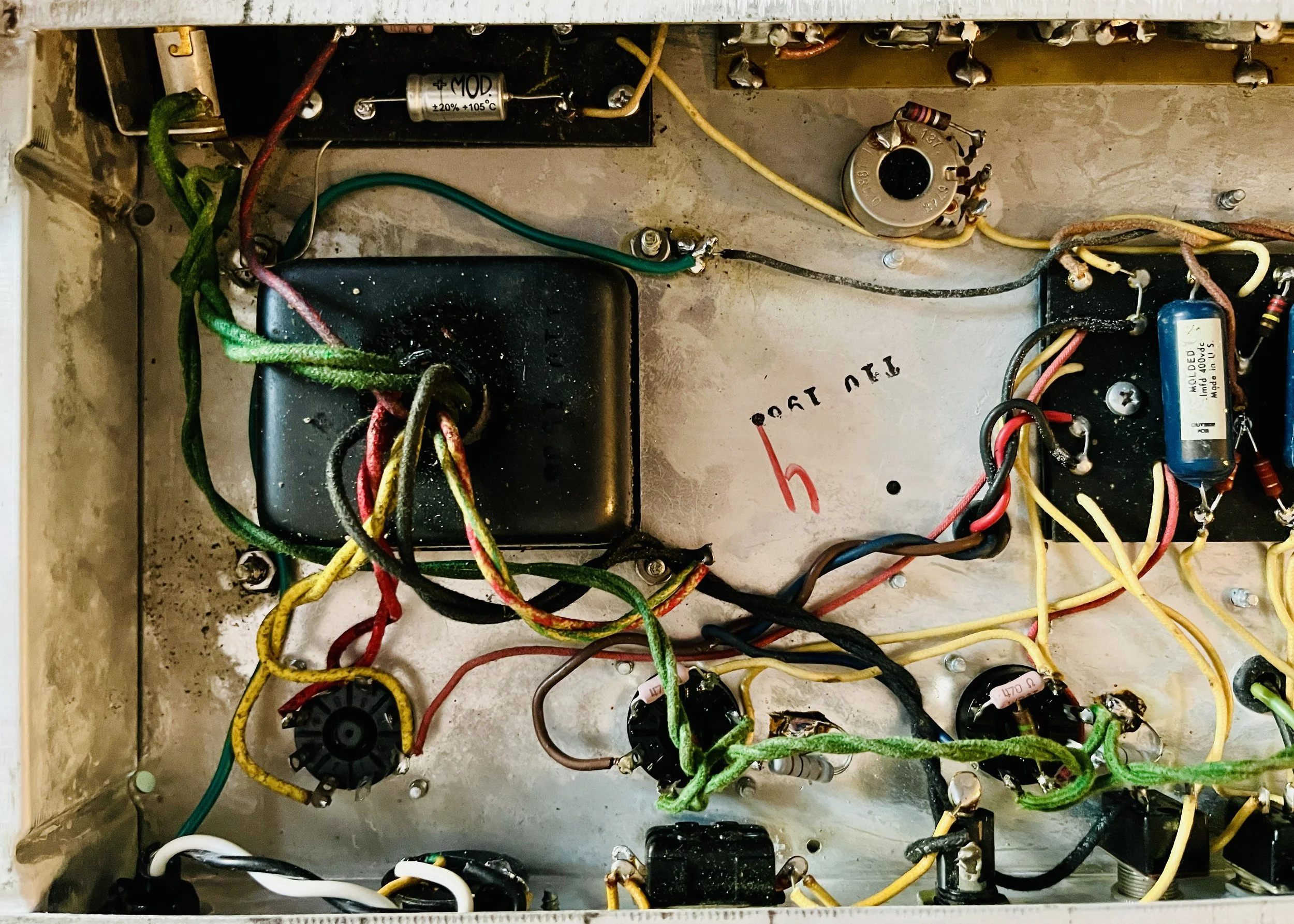

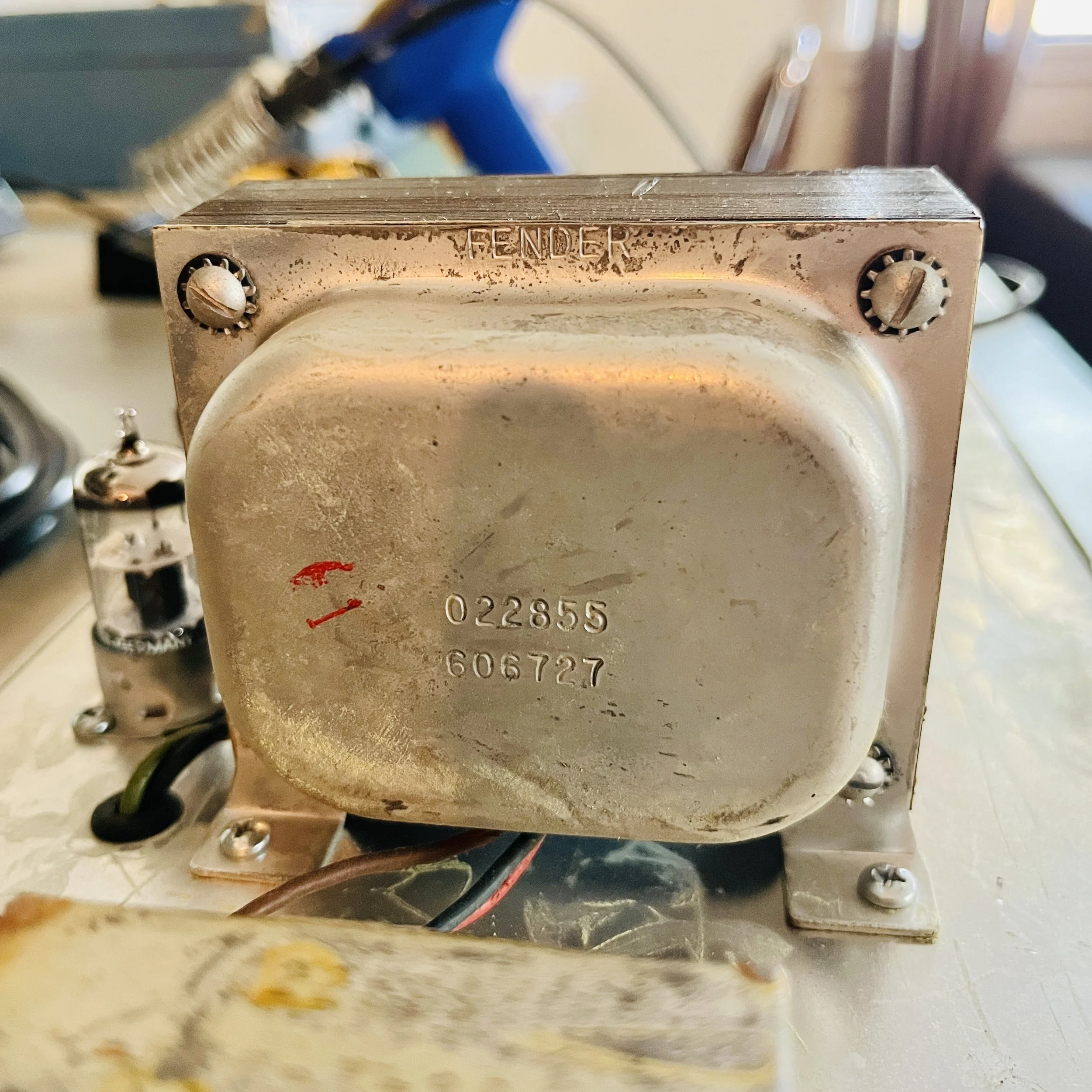

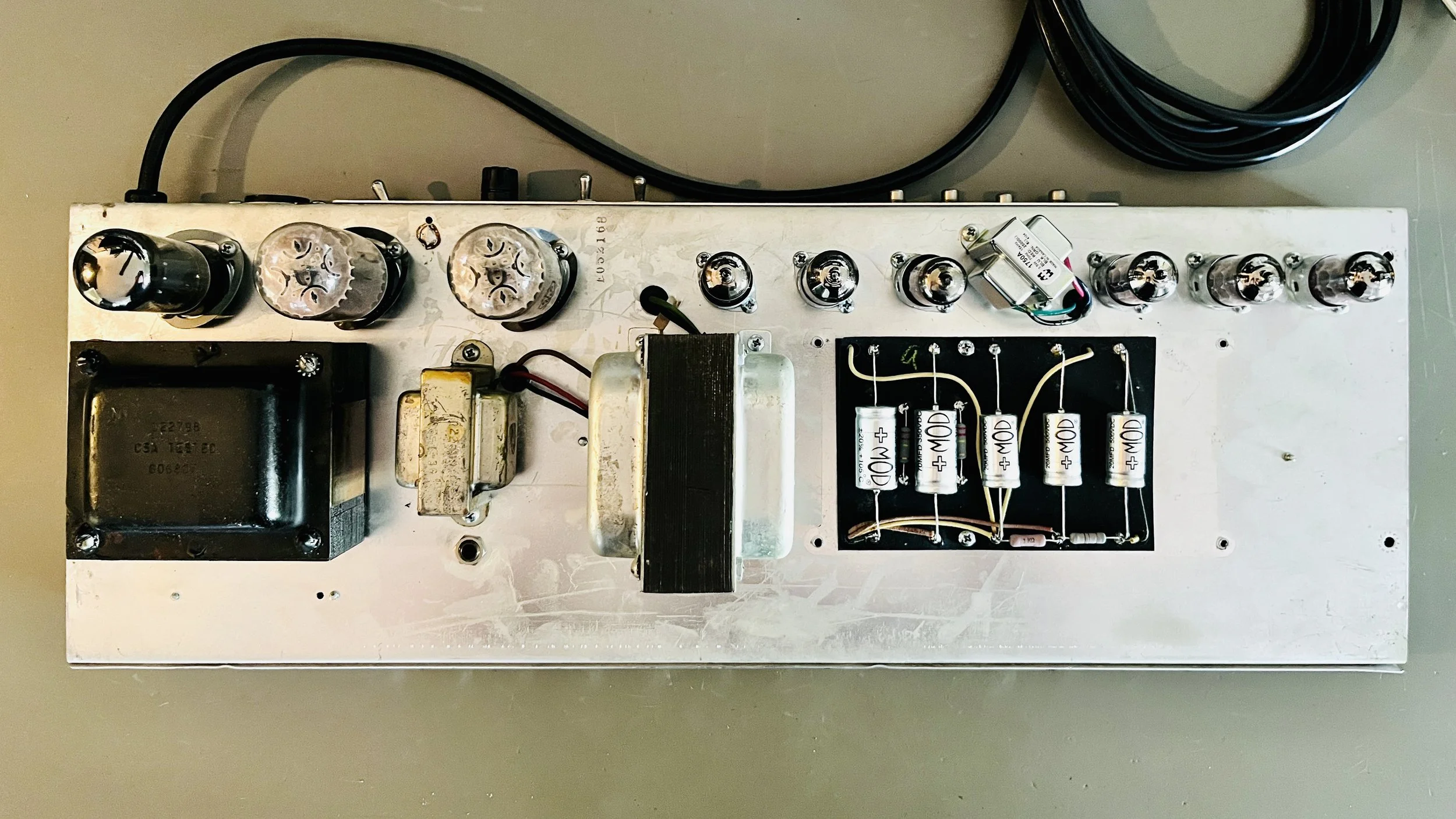

The amp was completely restored. All filter/bias/bypass caps were replaced with upgraded voltage and temperature rated MOD brand electrolytics. New 5 Watt Cement/2 Watt Metal Oxide power dropping resistors were installed for better reliability and lower noise floor. The cathode resistors for V3 and V6 were replaced with 2 Watt Metal Oxide type units due to heat damage. All plate resistors were replaced with 2 Watt Reduced Mass Metal Film type units for preventative maintenance and reliability. All screen resistors were replaced with 3 Watt Cement 470 ohm type units for same reasoning. A new 3 Prong AC cord was installed to replace the unsafe Two Prong unit which was present.

The Reverb Driver Transformer had a winding that had burned open internally, so the Reverb effect did not function at all. This was replaced with a Canadian made Hammond brand 1750A unit, which is an exact reproduction of the original transformer for tonal authenticity. A 1N4007 1000V 1A Diode was installed in the bias circuit for reliability. A brand new correctly sized 3AG 250V fuse was installed as the one in place was the wrong value. A .01uf 630v Mallory 150 film cap was used to mod the Trem circuit to stop it from ticking. The death cap was removed rendering the Ground switch deactivated for safety.

The original speakers were extremely loose off the baffle board due to the lock-nuts having come undone over the decades. One speaker was actually missing a nut holding it in place. These were all tightened or replaced, the speakers and cab stopped the rattling/buzzing that they came in with. The baffle board screws were all tightened as well for the same reasoning. All other hardware and the screws holding in the transformers were tightened as well.

The original tubes did not all test good and some were replaced. This was the lineup chosen: V1 = JJ 12AX7S, V2 = JJ E83CC, V3 = JJ 12AT7, V4 = RCA 7025, V5 = SOVTEK 12AX7WA, V6 = MULLARD ECC81, V7-V8 = RCA 6L6GC Matched Pair, V9 = MULLARD GZ34. These tubes were picked for best tone, and reliability. The 6L6GC's Fixed Bias was set to a conservative 43% Class AB Plate Dissipation with a B+ of 440VDC. The slightly cool bias just sounded right with this amp and will ensure those nice vintage RCA 6L6GC's will last longer. The tube sockets were all re-tensioned to stop loose tubes from potentially falling out and were then treated with De-Oxit to remove/prevent corrosion. The pots were sprayed out and the amp was cleaned inside and out. Amp now functions well.